I have a few habits when it comes to building kits….

The first habit is I ALWAYS read through all of the documentation before starting a build. I’ve learned the hard way that not all directions are accurate, and how something looks in one section, may be very different in a follow on section.

For this particular rocket, Giant Leap provided over 50 pages of documentation! On the one hand, that’s a lot of documentation. On the other, the modifications I was planning on making were sufficient that a fair amount of information I would have to disregard, or modify. And, of course, there are certain things I do in a build that will probably be different than the instructions, just because I’ve used certain techniques successfully in pre vious builds.

vious builds.

Once I read through the documentation, the first order of business was to build the motor mount. Starting off , I thought I would do something SUPER easy – – JBweld slimline motor retainer to the motor tube. This consists of sanding the outer diameter of the end of the motor tube to create a rough surface, prep the inside of the slimline with some masking tape to ensure the threads don’t get epoxy on them, coat the slimline and end of the tube, and push them together. Cool. First step was simple.

Oops! One of the modifications I was doing to the kit was to streamline the fins. This meant that the aft end of the fin tab would be a few i nches shorter than the stock build. Since the fin tab would be farther down the motor tube, another modification I had planned was extending the boattail to ensure it would buttress the end of the fin tabs. Once I extended the boat tail, I realized the (now glued in place) slimline would not fit through the now elongated boattail! The end of the slimline adapter has a small tab that’s meant to go behind the aft centering ring in a traditional build. So, as you can see on the left, the slimline adapter was now “stuck” about 2 inches shy of the end of the boattail. Obviously, this won’t work (unless I want the boattail to catch on fire….). Luckily, the metal tab was no match for a grinder

nches shorter than the stock build. Since the fin tab would be farther down the motor tube, another modification I had planned was extending the boattail to ensure it would buttress the end of the fin tabs. Once I extended the boat tail, I realized the (now glued in place) slimline would not fit through the now elongated boattail! The end of the slimline adapter has a small tab that’s meant to go behind the aft centering ring in a traditional build. So, as you can see on the left, the slimline adapter was now “stuck” about 2 inches shy of the end of the boattail. Obviously, this won’t work (unless I want the boattail to catch on fire….). Luckily, the metal tab was no match for a grinder ![]() I sure am glad I caught this – If I had installed the motor tube and center rings into the rocket airframe, grinding down that tab would have been almost impossible.

I sure am glad I caught this – If I had installed the motor tube and center rings into the rocket airframe, grinding down that tab would have been almost impossible.

The next part was fairly easy – install the rear, and forward centering rings. Since the fins are very long, they had to be cut to ensure they would fit around the rear center ring. This meant the rear center ring placement was CRUCIAL to ensure everything fit together. a few minutes of measuring, I had determined the exact position necessary for both center rings. The motor tube is made by Giant Leap, and is a hybrid phenolic tubing called “Magna Frame” The exterior of the tube was extremely slick, which makes for a difficult mechanical bond when epoxying two different types of materials together. I sanded down the tube in both positions I had determined for the centering rings . Now it was time to make the upper center ring.

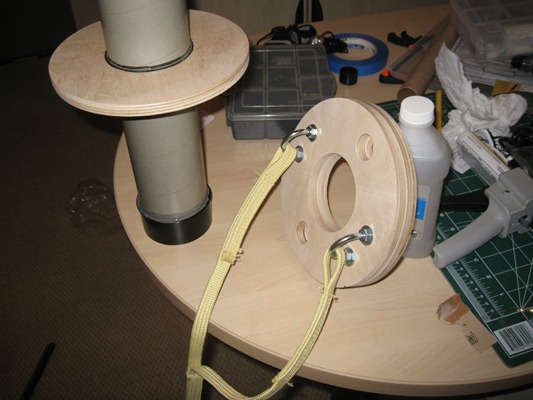

The upper center ring will be one of the critical components of the rocket, and will take a lot of the stress associated with both thrust, and the initial shock of parachute deployment. I opted to double the width of the centering ring, and install not one, but two u-bolts to attach the recovery harness. Once I epoxy the upper centering ring in place, I will never be able to touch the u-bolts again without ruining a big part of the rocket. I then connected a purpose-built harness to both u-bolts, which should distribute the recovery shock better between each ubol t. I also drilled two large holes in the centering ring, in preparation for adding foam later in the build process. Finally, I added some CA on both the upper, and lower nuts on the u-bolts to ensure they would not come loose during the extreme launch this rocket is likely to make.

t. I also drilled two large holes in the centering ring, in preparation for adding foam later in the build process. Finally, I added some CA on both the upper, and lower nuts on the u-bolts to ensure they would not come loose during the extreme launch this rocket is likely to make.

Yes, I am well aware my office is a MESS. Thank you for noticing, but don’t tell my wife!

Once the epoxy on the center rings had cured (24 hours – I have a lot of computer equipment in my office, so I can easily keep it about 90 degrees). I dry fit it into the airframe to ensure the center rings were in the right positions to allow for installation of the fins. I had dry fit it once already, but that was before  I glued the center rings – this was just a final check before I epoxied the motor tube and centering rings into the airframe. For good measure, I also installed the boattail, ensuring the slimline would go through the length, and the end of the boattail would buttress the fin tabs.

I glued the center rings – this was just a final check before I epoxied the motor tube and centering rings into the airframe. For good measure, I also installed the boattail, ensuring the slimline would go through the length, and the end of the boattail would buttress the fin tabs.

It’s always a little nerve racking when you build the fins MONTHS before commencing the build, wondering if it’s all going to fit together. After a little sanding, everything fit PERFECT. What’s fun about dry fitting the components together is it looks like a rocket! This is highly motivating to see what it’s going to look like a few weeks (or months…), and several steps later. I then dissembled everything, being very carful not to let the motor tube shift in any way. I then drew circles around the outer diameter of the centering rings, and removed the motor tube from the airframe. This allowed me to see exactly where the centering rings were going to go so I could sand internally to create a rough surface, and apply epoxy just to the areas in which the centering rings would be mounted. I reinstalled the motor tube, and set everything to the side to dry (another 24 hours… tick tick tick)

Looks like you had some of the glue leak out of your upper center ring when you clamped them together. Did you have any issues sanding it down if you used the hysol 120HP epoxy? I found it almost impossible to sand once cured.

I cleaned up the glue right after I took the photo. You are right about this epoxy. If you try and sand it down, it just wears the wood away around the epoxy. That’s one of the reasons I am thinking about making my fillets out of pro-set, so I can sand before fiberglassing.

What are the fins made of? Can you describe the components a little more. Is that pml tubing?

Good thoughts. I will post a list of materials. The fins are an e-glass honeycomb matrix that I glued edging onto